Less space and weight for FSRU heating

On and FSRUs, temperature control is a critical but space-consuming application. Framo FSRU heating systems combine open and closed loops, which allows both parts to be optimized and streamlined.

Proven reliability

FSRU heating have traditionally been managed by large conventional pumps, installed in a pump room. Today, however, there is a more compact and economical solution, that eliminates the use of pump room

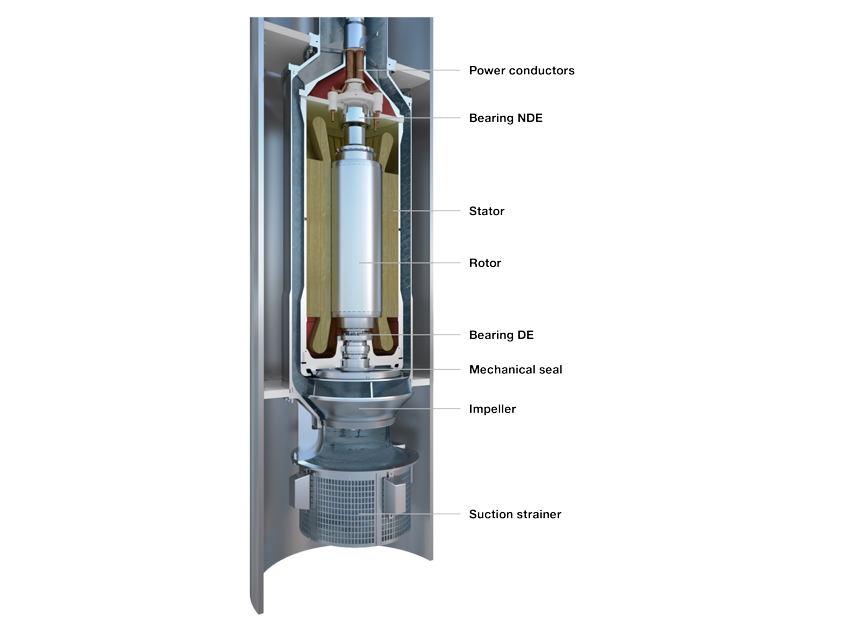

Built with leading heat transfer technology, Framo FSRU heating systems combine a closed thermal loop with an open loop, which leads to system-wide savings in space, weight and cost. Integrated with the hull, they replace the use of pump room with compact seawater lift pumps using the Framo cable-free concept

Saving in two steps

Savings can be found in both the open and closed loops of these integrated Framo systems.

In the open seawater loop, the pumps, filters and heat exchangers are configured to provide the right cooling or heating performance with the minimum amount of equipment. The effect this has on power consumption is negligible, yet it reduces weight by 25% and creates a 15–20% savings in CAPEX.

In the closed freshwater loop, compact cable-free electric submersible pumps replace the topside pump modules. These take up no space on deck and create equally dramatic weight savings

Freeing up space and time

The total result is a massive reduction in both footprint and weight, which means less CAPEX, lower OPEX and space topside that can be used for other processes. In addition, the seamless system interface ensures easy access that reduces the time needed for maintenance work.

Features

- Hull-integrated system with no topside installation

- Compact submersible pumps for both seawater lift and closed-loop cooling

- Optimum operating conditions

- Greatly reduced installation weight

- Significantly lower CAPEX

Contact Us

Overview of Solutions

Technical Brochures