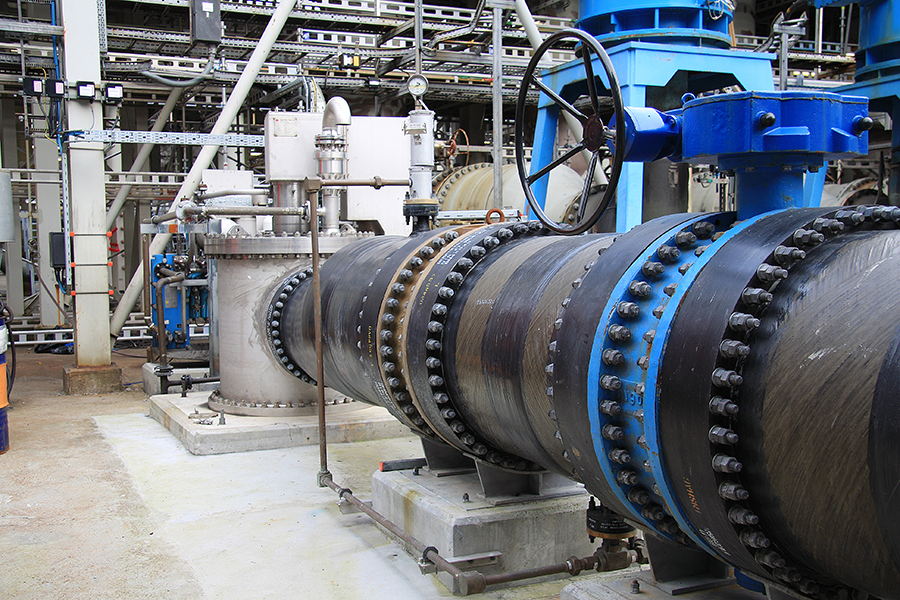

Framo scope of delivery: Fire water pumps.

Why Framo Offshore Solutions?

Supporting onshore installations

Framo pumping systems are most prevalent in marine and offshore applications, but our technology can be found on land as well. At coastal facilities for oil and gas production, our seawater lift pumps, fire water pumps and power generators solutions also come into play.

Proven strengths in new areas

Traditionally, onshore facilities have used line shaft pumps to supply water for cooling or firefighting. Usually installed on the quay or in the water intake pit, they typically comprise a top-mounted vertical motor that drives a 10–15 m pump shaft with impeller.

Nonetheless, a growing number of companies have seen that the Framo advantage can apply on land. Submersible pumps with short stiff shafts provide cost-saving reliability, in onshore applications as well as offshore.

Our first onshore deliveries were in the early 1980s, when we supplied fire water pumping systems for the Stavanger area of Norway and the west coast of Sweden. Recent customers include prominent gas terminals, as well as the Technology Centre Mongstad, a joint venture between the Norwegian state, Statoil and Shell and Sasol. The latter site is the world’s largest testing facility for CO2 capture conditions.

Case Highlights: Land Based Production with Our Solutions

Statoil - Melkøya Gas terminal

Framo scope of delivery: Fire water pumps.

Statoil, Shell, Sasol - Technology Center Mongstad

Framo scope of delivery: Sea water lift pumps.

Safe and secure handling of underground storage

Underground storage of crude oil, natural gas and oil products is an increasingly attractive means of securing an energy supply. Having delivered submersible pumps to cavern applications since the 1970s, Framo can provide a hydraulic or electric pumping concept for any storage.

Performance that runs deep

Four decades ago, we supplied the first Framo hydraulic cavern pumping system to Norway’s Mongstad refinery. Since then we’ve delivered over 200 hydraulic and cable-free electric submersible cavern pumps worldwide. Among them are the twelve largest electric submersible pumps in the world, each with a capacity of 5000 m3/h, which have been operating at Mongstad crude oil

terminal since 1987.

The sheer dimensions of underground storage caverns make large pump capacities a must.

But pump reliability is equally important, as is the ability to operate in the cavern’s potentially explosive atmosphere. Framo submersible pumps meet all of these requirements and offer major advantages for cavern facilities.

In fact, Framo is one of the few pump suppliers in the world with strong capabilities in cavern pumping. With our experience in the application and our high level of pumping expertise, we can provide the most suitable concept and equipment for any cavern storage service.

Case Highlights: Land Based Storage with Our Solutions

Framo scope of delivery: Crude cavern offloading and seepage water pumps.

Statoil - Mongstad Crude Oil Caverns

Framo scope of delivery: Crude cavern offloading and seepage water pumps.

Contact Us

Overview of Solutions

Technical Brochures