Framo hydraulic fire water pumps for rapid response

Framo hydraulic fire water pumping systems, with single-stage pumps that rotate slowly during standby, offer a minimal start load and the best possible preparedness.

Faster to bring online

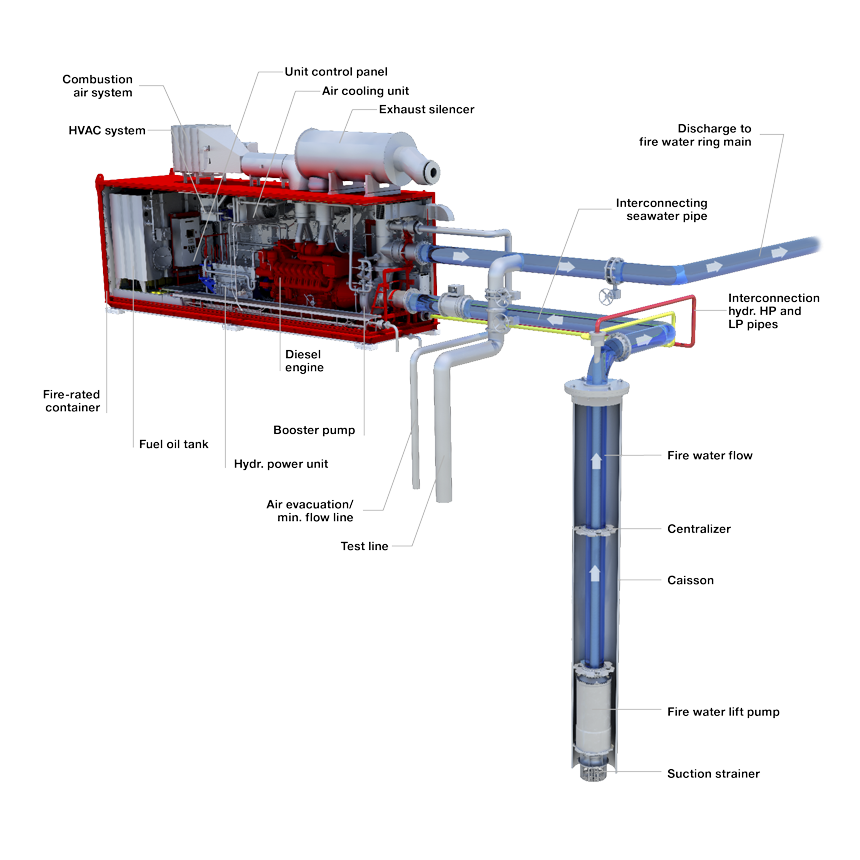

Framo hydraulic fire water pumping systems use a submerged, hydraulically driven pump. This pump lifts the water to deck level, where it feeds into a pump that is directly driven by the diesel engine. Consequently, the diesel engine’s start load is kept to a minimum.

Typically, there is a 30/70 load split between the submerged pump and the direct-driven pump. This means the main engine start load is just 30% of its full load. As a result, the whole firefighting system can be brought online much faster and with less start load on the engine.

Always in motion

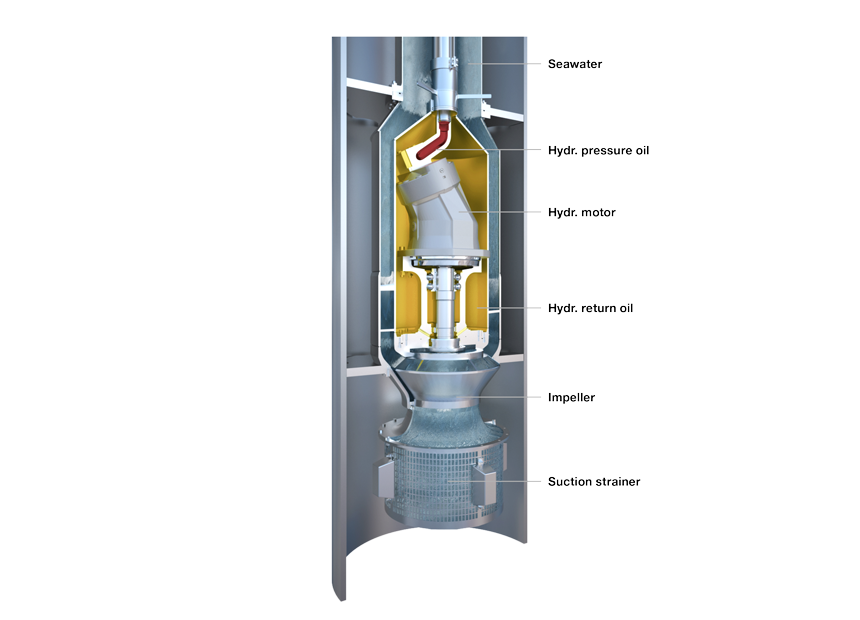

The submerged lift pump is a single-stage, end-suction centrifugal pump driven by a hydraulic motor. Suspended in the water from a riser pipe, it has a short, stiff shaft that minimizes strain and vibration. Water is delivered through the riser pipe to the main pump above.

The lift pump runs continuously at low speed (40–50 rpm) in standby mode, driven by a flow of low-pressure hydraulic fluid circulated by a small electrically driven pump. The fluid is circulated to and from the lift pipe through concentrically mounted pipes within the riser pipe.

Smart, protected construction

The riser pipe is constructed of flanged sections, while the hydraulic oil pipes inside it are fitted with connectors. This construction protects the hydraulic fluid transmission and enables the lift pump to be installed without an external caisson.

The diesel engine package comes complete with fuel tank, starting system and ancillaries, which areinstalled on a single skid and completely enclosedin a fire-protected, containerized module.

Features

- End suction to ensure maximum NPSH (net positive suction head) availability

- Submerged lift pump with single-stage, end-suction design

- Continuous rotation of the submerged lift pump in standby mode

- Low start load

- Continuous condition monitoring of the submerged lift pump

- Compact, low-weight system

Available options

- Electric or pneumatic start system in accordance with NFPA 20, with optional hydraulic black start

- Several options for combustion air and exhaust gas systems, including cooled exhaust under 200cc

- HVAC that can be delivered for pressurization in Zone 2 areas

- Anti-surge device with air release and vacuum breaker valve with optional minimum flow and/or test facilities

- Diesel fuel oil system for 12, 18 or 24 hours

- Local PLC-based control panels in communication with fire and gas system

- Electrical distribution panel with optional cabinet for hazardous areas

- Fire and gas detection within container Fire extinguishing systems

- AFFF system including tanks, pumps and control

Technical data

Oil and gas pumping systems

Technical brochures

Stay updated

Contact form

Thank you for contacting us

We will get back to you as soon as possible