A valuable difference

Full-scale testing prior to delivery ensures reduced commissioning time and promised product performance.

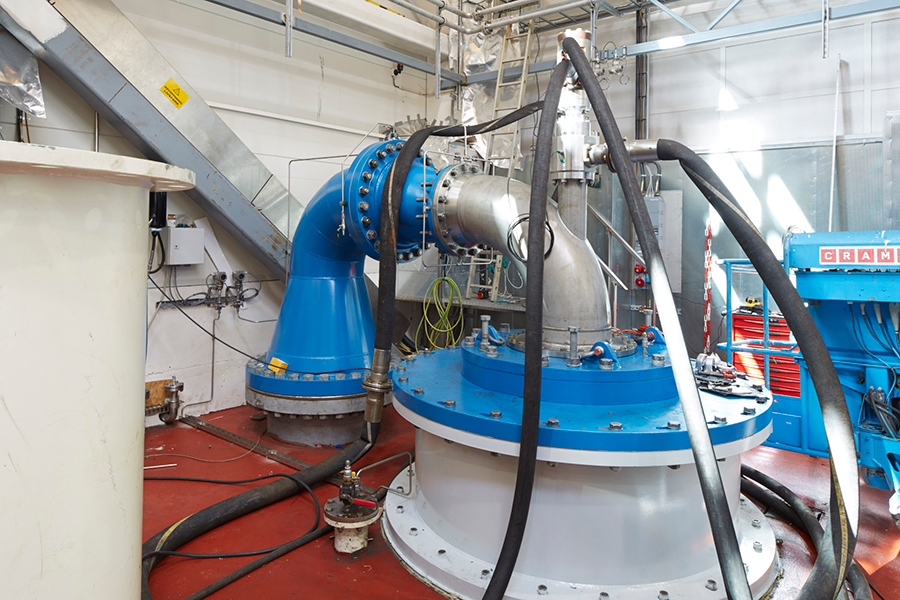

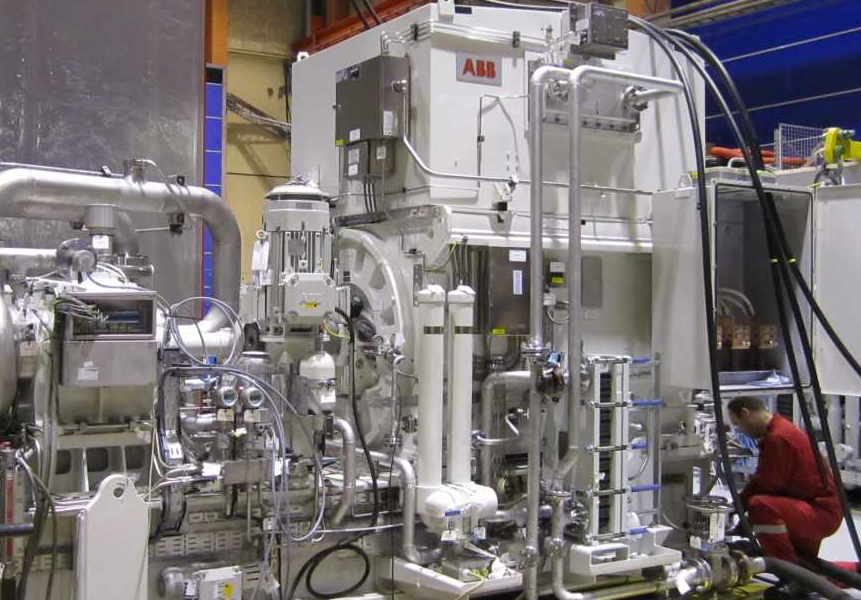

Full-scale testing in-house

Before any Framo product is delivered, it undergoes comprehensive testing and quality control. At our own facilities in Norway, in direct connection with our manufacturing, we perform full-scale string testing of Framo pumping systems at rated capacity, pressure and speed. Likewise, we perform extensive qualification testing on critical components.

This reduces the commissioning time needed, and it ensures that our products will perform as promised. In the offshore industry, where project schedules are a critical driver, it makes a valuable difference.