Materials

All pump, pipe stack and top plate materials are selected for their superior characteristics at extreme low temperatures. Components are predominantly crafted from 316 stainless steel, with wear rings made of aluminium bronze CC333G, and power transmission conducted via aluminium rods. Insulation and spacer pieces, designed for insulation, primarily consist of PTFE and PEEK materials.

Maintenance

Under normal operating conditions, the Framo SLG Pump requires servicing every 25,000 operating hours or every 5 years, aligning with vessel dry dock schedules. During maintenance, the pump undergoes disassembly and inspection, with minimal parts requiring replacement. Bearings are replaced every 5 years, while wear rings are replaced every 5–10 years based on their condition. Framo SLG pumps are seamlessly integrated into our existing service programme, which boasts service offices and technicians located worldwide.

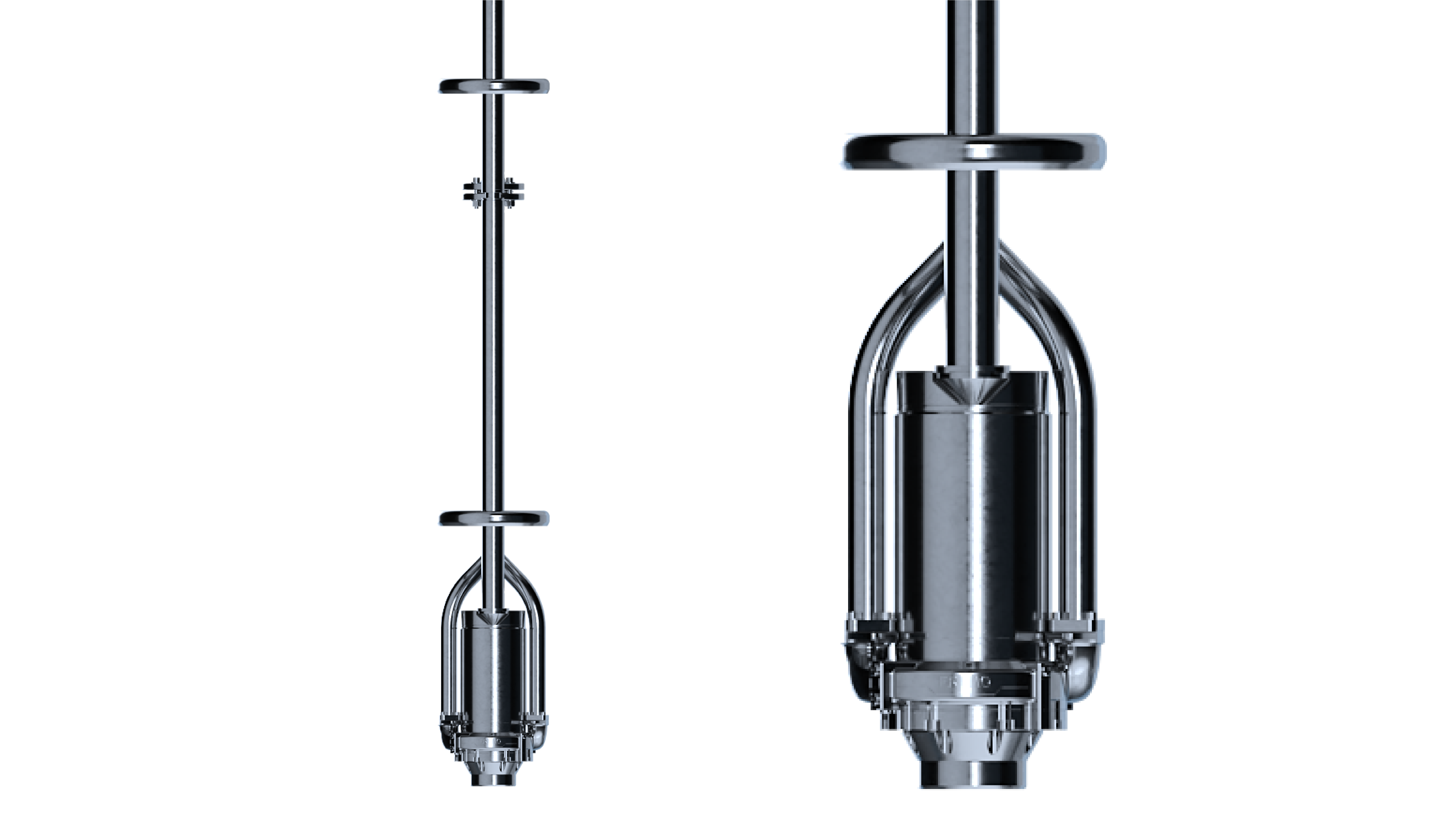

Framo SLG series

|

SLG 25 - 2/4S |

Capacity: 1–10 m3/h |

|

SLG 50-1/2S |

Capacity: 7.5–40 m3/h |

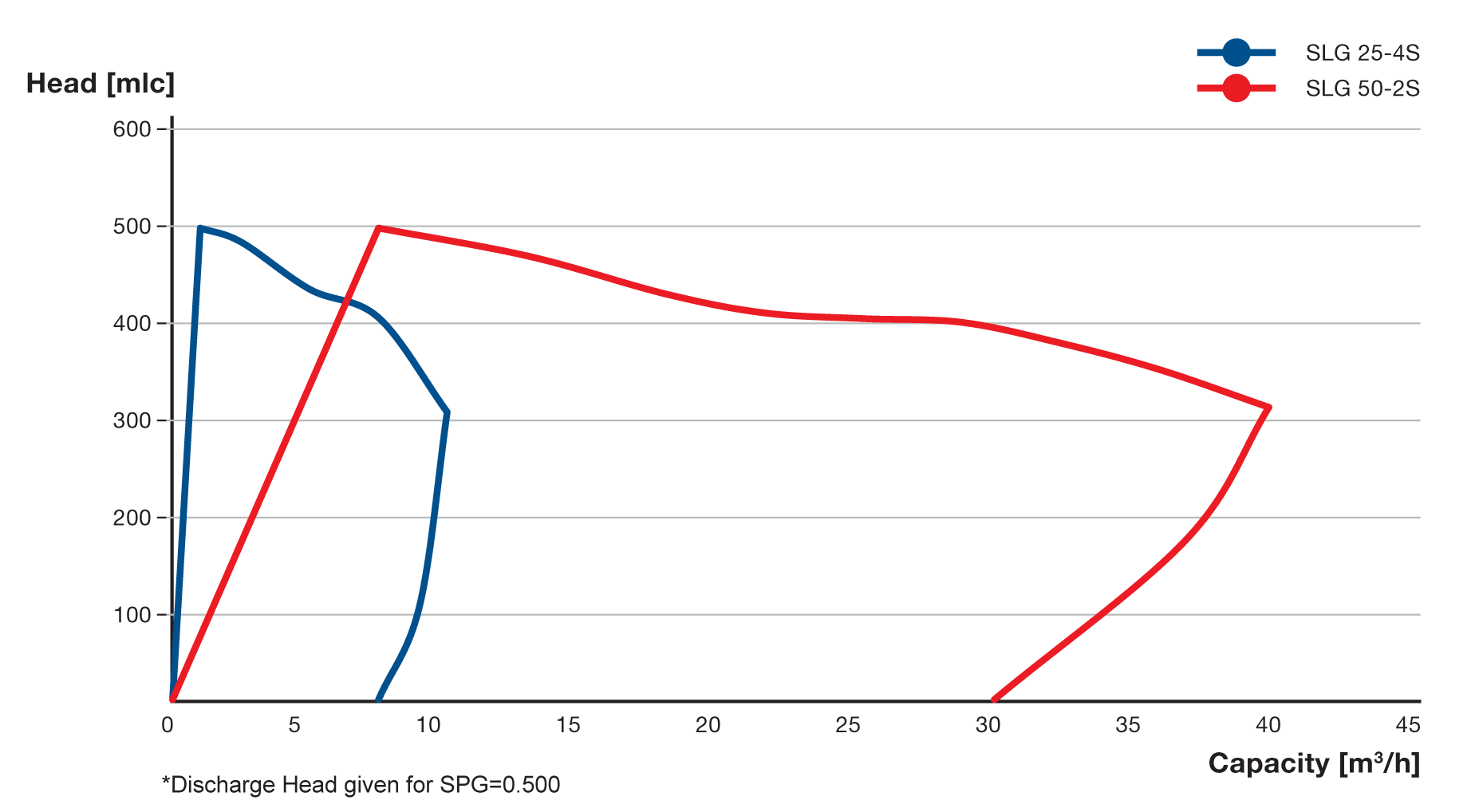

Pump performance curve

Rune Sakslo

Jens Mildestveit

Download brochure

Stay updated

Contact form

Get the latest news and product information in your inbox.

Thank you for contacting us

We will get back to you as soon as possible